The Model 9EE and 18EE SoapLaunchers utilize any soap stick diameter, up to 1-3/8”, and have a capacity of 9 or 18 sticks (M-9EE or M-18EE). The Model 18 is taller than the M9 and drops 2 sticks every cycle. These SoapLaunchers are solar-electric (12 volt) and use the Select-and-Go™ dial processor. Like our other Launchers, the EE Launchers are SCADA ready. The Model 9EE (or 18EE) is suitable for remote or difficult to reach well locations that benefit from regular introduction of surfactant.

With no supply gas requirements and no equipment going downhole, the Model 9EE (or 18EE) will help keep both CAPEX and OPEX reasonable. WP is 2000#. For a 3000# working pressure rating, add an ‘H’ to the item number (ex. M-18H-EE). A 5K version is available as a non-stock item.

When the flow rate from the well is below a certain threshold, the Model EE Launchers can be used to drop the soap stick into the flowing well.

When the flow rate is greater than the permissible rate, the operator has 2 options for maintaining unattended production:

● install an ABV-CM (ABV with a built-in Dial Processor for off-time selection);

● let the RTU trigger the Launcher to drop a stick when the RTU closes its flow line valve;

It is recommended that an ABV w/Control Module be installed into the flow line to shut-in the flow from the well for a minimum duration while the falling soap stick transits the wing block tee (view the Maximum Flow Rate Chart).

Thereafter, the ABV reopens the well to flow.

Model 9EE Video

This video is a Model 9EE operating an ABV (actuated ball valve) in the flowline. The duration of the operation is 2 minutes but the 9 second video was filmed at high speed. The flow rate from this location exceeds the 250 MCFD limitation. Therefore, 1 minute after the ABV stops the flow from the well, the EE drops a soapstick and, 1 minute later, the ABV reopens the well to flow. At the rate of stick fall, the soapstick is ~3000’ below the surface when the reopening occurs.

Comparing the EE to the Model P and Model E

All 3 of these Launcher versions drop soap sticks based on time or on the command of an RTU. All 3 versions can control flow from the well if the appropriate valve is installed in the flow line. The EE is 40% less expensive than the P or E but the EE is less flexible. The EE has a Dial Processor with a limited range of settings whereas the P and E are infinitely programmable, for flow and off time, up to 99 hours.

If the ambient temperature is freezing but not in a climate that demands heat tape, the Model E and Model EE are not as prone to associated issues as the pneumatic-actuated P model would be.

Model EE

Available in a 9 or 18 stick version

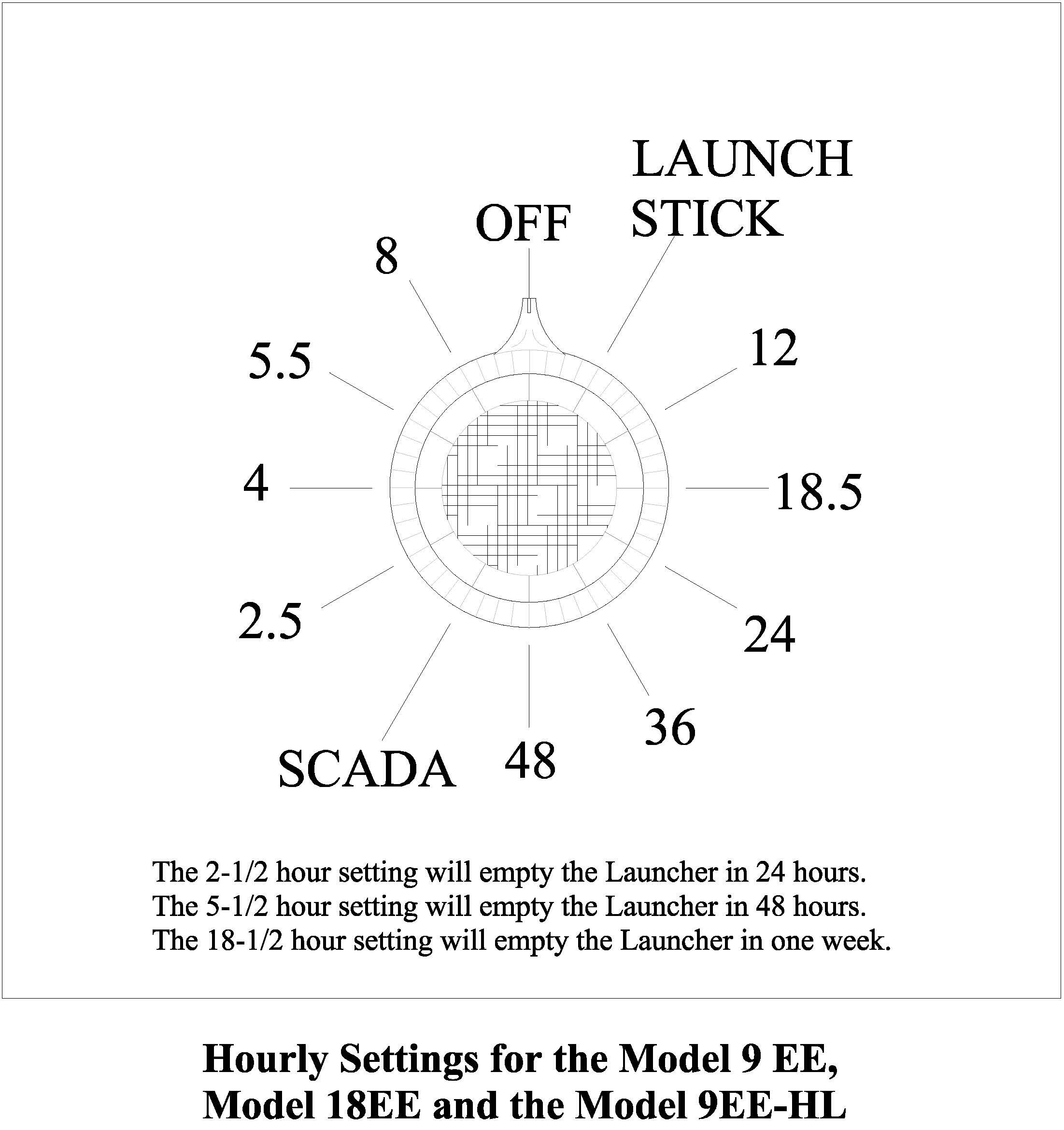

9 Position Dial-n-Go Processor – 2.5 to 48 hours cycle time

Emissions-free 12v Electric Actuation

Scada ready with a pre-programmed 1 minute launch delay feature

ABV-Control Module-ready with 10 distinct options for shut-in duration

Pre-programmed for launch delay using an ABV-CM

Higher cold tolerance versus the Model P

Lowest sticks-per-unit cost

No gas supply pressure required

Model E

9 or 18 stick option

Keypad with Digital Display – 1 minute to 99 hour cycle time options

Program to drop 1 or more sticks each cycle (useful for certain horizontals)

Programmable temperature lockout (to reduce frozen flow line issues)

Displays the quantity of sticks remaining

Emissions-free 12v Electric Actuation

Scada ready – will wait on the RTU to initiate a stick-drop

ABV-Power Module ready – 1 minute to 99 hour shut-in duration options

Programmable for venting to the tank via ABV-Power Module or other electric valve

Programmable Launch Delay setting, an asset for weaker locations

Controls the flow from the casing and/or the tubing in most any combination

More options, more flexible than the Model EE

Ideal for low pressure gathering systems

Model P

9 or 18 stick option

Keypad with Digital Display – 1 minute to 99 hour cycle time options

Option of dropping 1 or more sticks each cycle

Programmable temperature lockout

Displays the quantity of sticks remaining

Gas operated actuation – ready to control Kimray type motor valves

Requires 35 PSI from the tubing or casing source

Scada ready – will wait on the RTU to initiate a stick-drop

Flow Control – 1 minute to 99 hour shut-in duration options

Programmable for venting to the tank through a 2nd pneumatic motorvalve

Programmable for direct flow from the casing through a 2nd pneumatic motorvalve

Programmable for long term Launch Delay setting, helpful when pressure build-up is required

Displays error messages and activity history

Includes a self-dumping drip-pot to protect the soapsticks and the control system

Smart enough to predict regulator clog failure and flag the operator

Comparisons Continued

How do the other 2 Launchers compare to the EE, E and P versions?

The M-2 Midnight Launcher holds 2 sticks only and drops them both at the same time. It can be loaded with the larger 1-5/8” diameter stick which, together, is the surfactant equivalent of 3 of the standard 1-1/4” soapsticks. The M-2 can operate an ABV in the flowline to shut-in the well. It has 7 hourly setting options and is the Launcher with the lowest cost.

The Model 9EE-HL Launcher is an M-9EE sitting atop a lower chamber. The -HL is not offered with an 18 stick capacity. The purpose of the lower chamber is to isolate the soapsticks from exposure to line pressure when the line pressure exceeds 350 psi. The maximum permissible line pressure for the M-9EE-HL is 850 psi.